History

Published in the Preview Arts & Entertainment section of The Villager. Written by Sascha Brodsky

The last… Renaissance craftsman

The last… Renaissance craftsman

Ranieri Casting is to sculptors what The Met is to an opera fanatic. The busy loft-space on Prince St. is the regular haunt of many involved with the New York sculpture scene; from Frank Stella and Robert Longo to sculpting celebrities like Yoko Ono and Anthony Quinn.

Friendships have been forged and broken in the waiting area, which is wallpapered with pictures of clients and their work.

“Over many years working here you get to know people,” says Anita Huffington, whose sculpture “Jazz” was cast at Ranieri and is now owned by President Clinton.

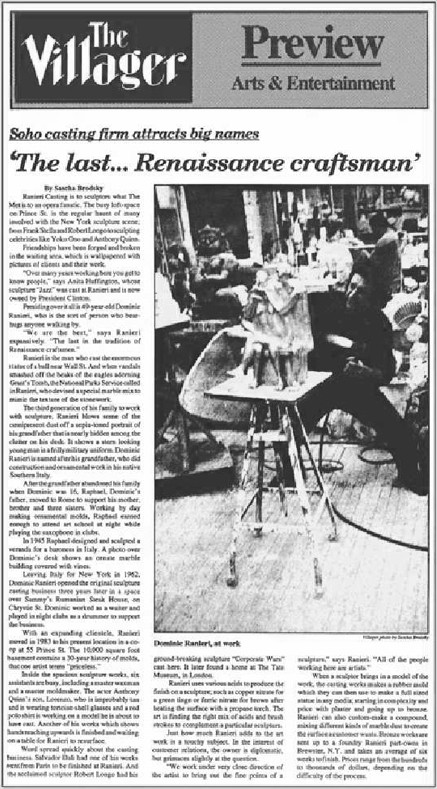

Presiding over it all is Dominic Ranieri, who is the sort of person who bearhugs anyone walking by.

“We are the best,” says Ranieri expansively. “The last in the tradition of Renaissance craftsmen.”

Ranieri is the man who enlarged the enormous statue of a bull to 16 feet near Wall St. And when vandals smashed off the beaks of the eagles adorning Grant’s Tomb, the National Parks Service called in Ranieri, who devised a special marble mix to mimic the texture of the stonework.

The third generation of his family to work with sculpture, Ranieri blows some of the omnipresent dust off a sepia-toned portrait of his grandfather that is nearly hidden among the clutter on his desk. It shows a stern looking young man in a frilly military uniform. Dominic Ranieri is named after his grandfather, who did construction and ornamental work in his native Southern Italy.

After the grandfather abandoned his family when Dominic was 16, Raphael, Dominic’s father, moved to Rome to support his mother, brother and three sisters. Working by day making ornamental molds, Raphael earned enough to attend art school and night while playing the saxophone in clubs.

In 1945, Raphael designed and sculpted a veranda for a baroness in Italy. A photo over Dominic’s desk shows an ornate marble building covered with vines.

Leaving Italy for New York in 1961, Dominic Ranieri opened the original sculpture casting business three years later in a space over Sammy’s Rumanian Steak House, on Chrystie St. Dominic worked as a writer and played in night clubs as a drummer to support the business.

With an expanding clientele, Ranieri moved in 1983 to a co-op at 55 Prince St. and have since moved to 27-01 47th Avenue, Long Island City. The over 10,000 square foot basement contains a 30-year history of molds, that one artist terms “priceless.”

Inside the spacious sculpture works, six assistants are busy, including a master Waxman and a master moldmaker. The actor Anthony Quinn’s son, Lorenzo, who is improbably tan and is wearing tortoise-shell glasses and a red polo shirt is working on a model he is about to have cast. Another of his works which shows hands reaching upwards is finished and waiting on a table for Ranieri to resurface.

Word spread quickly about the casting business. Salvador Dali had one of his works went Paris to be finished at Ranieri. And the acclaimed sculptor Robert Longo had his ground-breaking sculpture “Corporate Wars” cast here. It later found a home at The Tate Museum, in London.

Ranieri uses various acids to produce the finish to a sculpture, such as copper nitrate for a green tinge or ferric nitrate for brown after heating the surface with a propane torch. The art is finding the right mix of acids and brush strokes to complement a particular sculpture.

Just how much Ranieri adds to the art work is a touchy subject. In the interest of customer relations, the owner is diplomatic, but grimaces slightly at the question.

“We work under very close direction of the artist to bring out the fine points of a sculpture,” says Ranieri. “All of the people working here are artists.”

When a sculptor brings in a model of the work, the casting works makes a rubber mold which they can then use to make a full sized statue in any media, starting in complexity and price with plaster and going up to bronze.

Ranieri can also custom-make a compound, mixing different kinds of marble dust to create the surface a customer wants. Bronze works are sent up to a foundry Ranieri part-owns in Brewster, N.Y. and takes an average of six weeks to finish. Prices range from the hundreds to thousands of dollars, depending on the difficulty of the process.